Research Capacity

-

Design

It challenges design that realizes customer

impressions based on global processes.Based on the accumulated know-how in line with the development of the automobile industry, it is designed to show optimal performance.

-

Analysis

The analysis achieves the best product performance

and optimal design models using virtual simulationIt can reduce the time and cost of product development by predicting product performance with the help of virtual simulation.

Moreover, it realizes the best design model through optimal design methods on performance, price and mass of products. -

Test

Based on overall test and verification, we challenge the best quality products.

We fully validate and develop products in the process of product development through simulating actual field conditions on durability, performance and reliability test.

Design

It challenges design that realizes

customer impressions based on global processes

it is designed to show optimal performance.

-

- Hydrogen Mobility System Component design

-

-

- MEMS chip applied structural design technology

-

- Micro package bonding and assembly process technology

- Airtight/Waterproof structure design

- Catalyst design for hydrogen detection

- Complex function integrated structural design technology

-

- Signal processing technology

-

- Signal integrity, Power integrity analysis technology

- Electromagnetic shielding and noise filtering circuit design

- Signal calibration and self-diagnosis algorithm design technology

-

- Long-term operation durability design

-

- Product long-term driving assessment reflection design

- Design of durable life model for accelerated durability test

-

-

- Electric Mobility System Component design

-

-

- Valve-integrated modular design technology

-

- Actuator part selection and operation part design

- Driving electric field design through motor and gear

-‘Valve + Sensor’ integrated packaging design

-

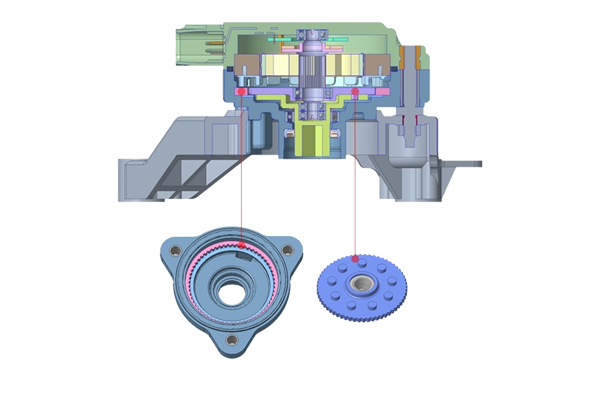

- Motor Design

-

- Shape design through electromagnetic analysis

- Motor coil winding design technology

- Motor driving electric field design technology

-

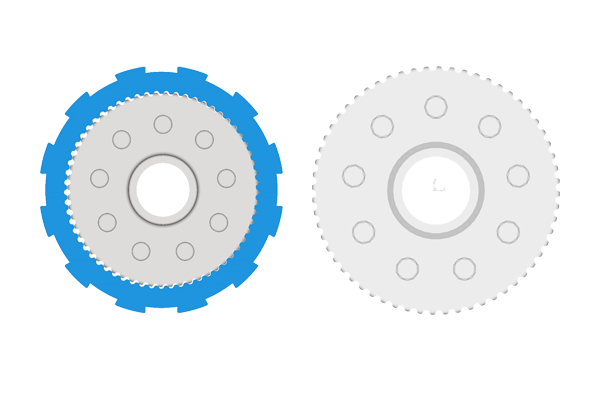

- Gear design

- - Gear design according to required driving performance

-

-

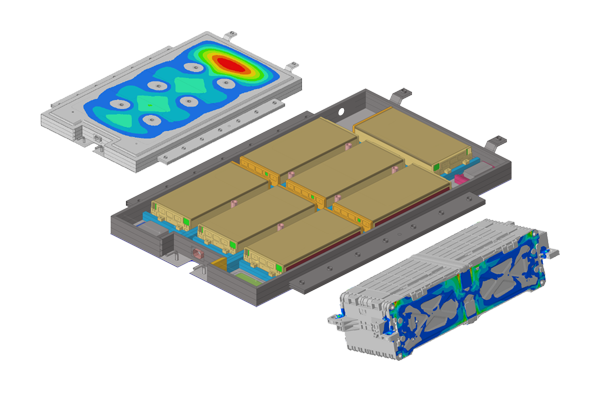

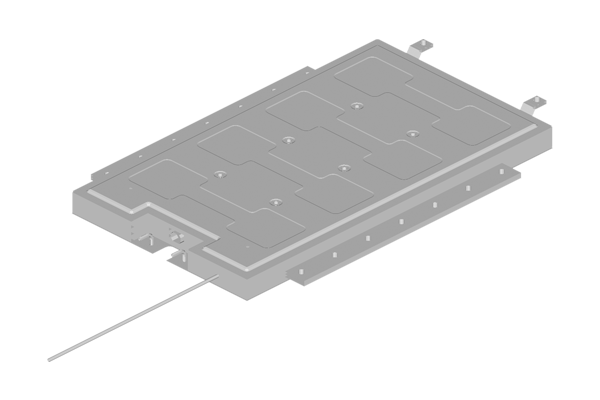

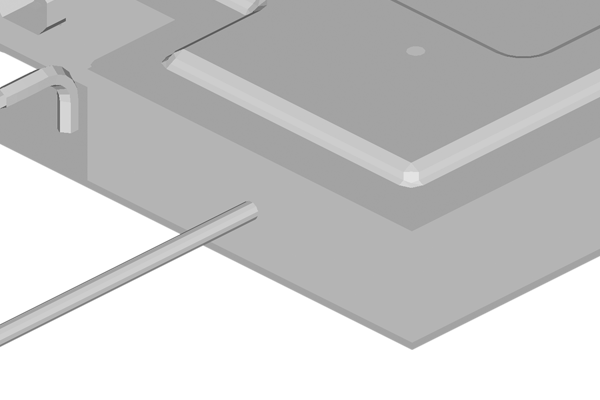

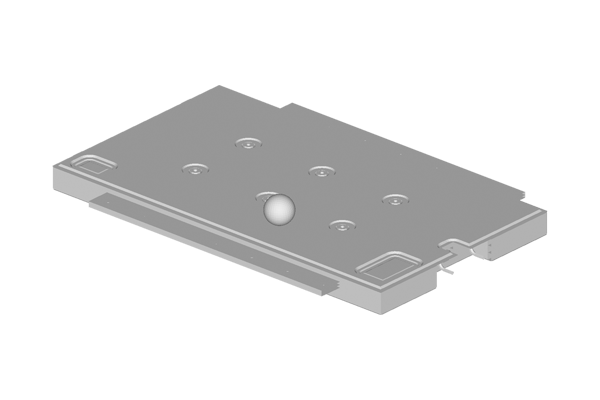

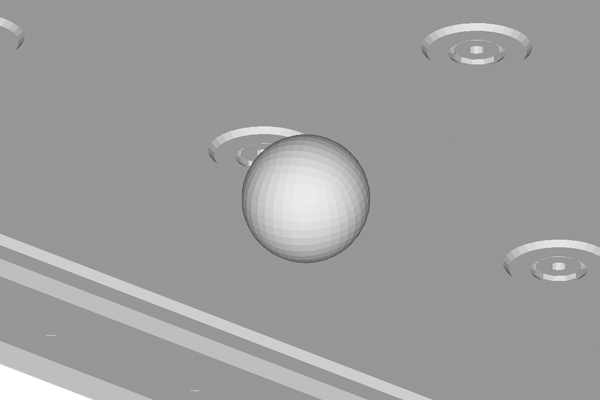

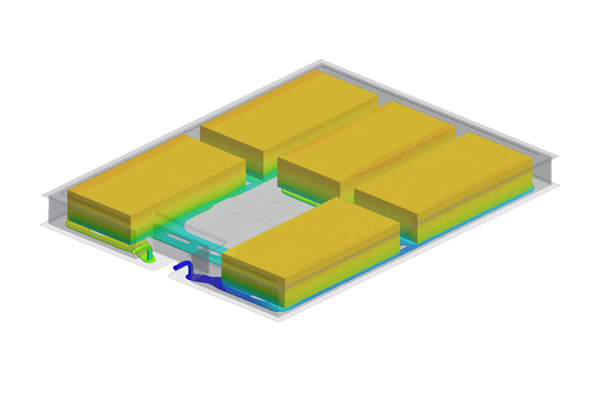

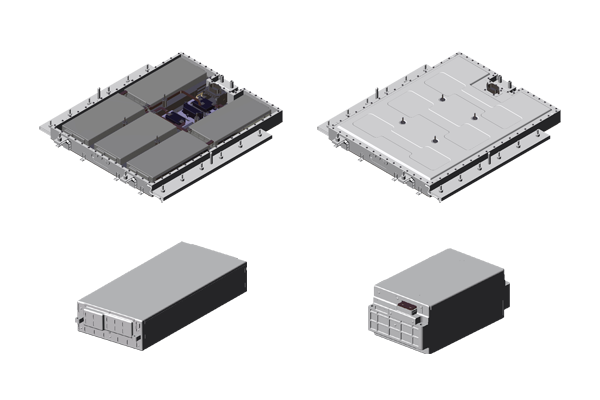

- Battery component design

-

-

- Layout design

- - Vehicle mounting interface part and battery module layout structure design

-

- Safety design

- - Shock, crash, compression and environmental battery safety design

-

- Performance design

- - Temperature management mechanism design for battery charging and discharge optimal efficiency performance

-

- Control design

- - Control algorithm design for safe charging, discharge and lifetime management of battery cells

-

-

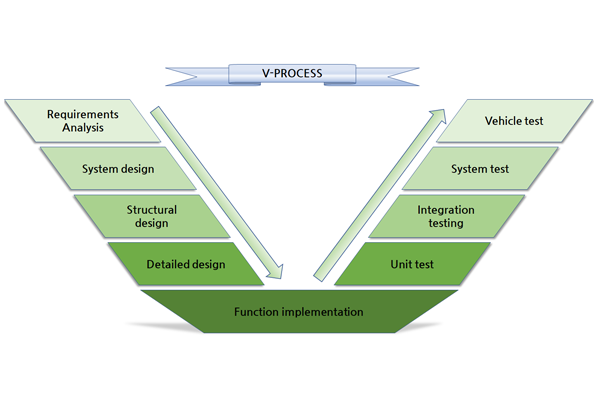

- Electric components design certification

-

-

- ISO 26262

- Functional safety international standard applied to electrical/electronics equipment

-

- A-SPICE

- Automobile S/W Development International Standard

-

- CYBER SECURITY

- Cyber security system standard

-

-

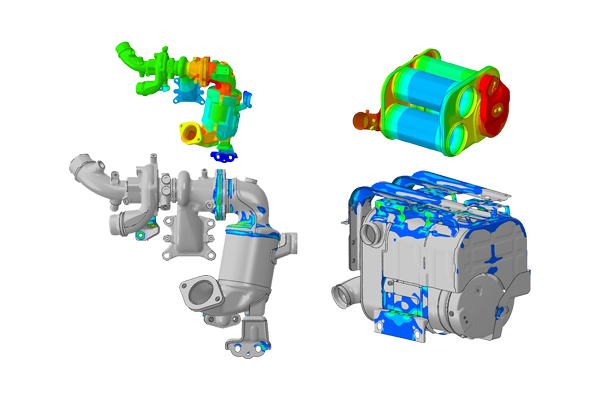

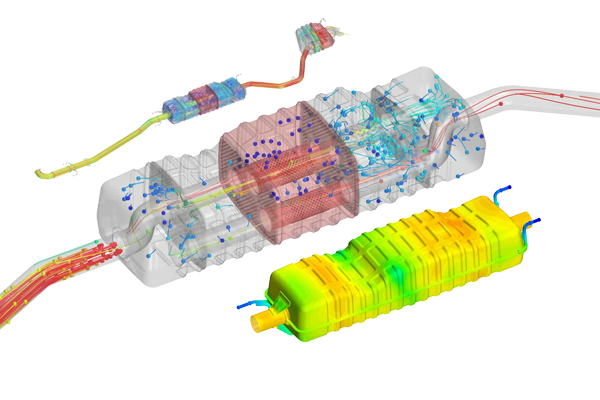

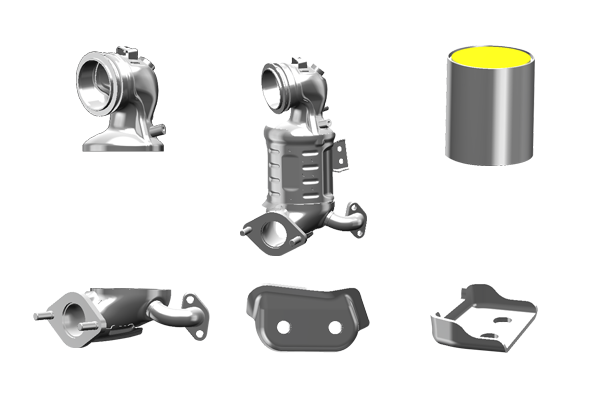

- Design Parts of Exhaust Aftertreatment system

-

-

- Layout

- Canning package design mating with each specific vehicle design

-

- Gas flow control

- Design the gas flow route in canning package suitable for gas purification reaction of catalyst in canning package

-

- Durability

- Design the durability against high temperature and vibration of the engine

-

- Assembility

- Easy to assemble to engine or vehicle level with regards to GD&T applied

-

-

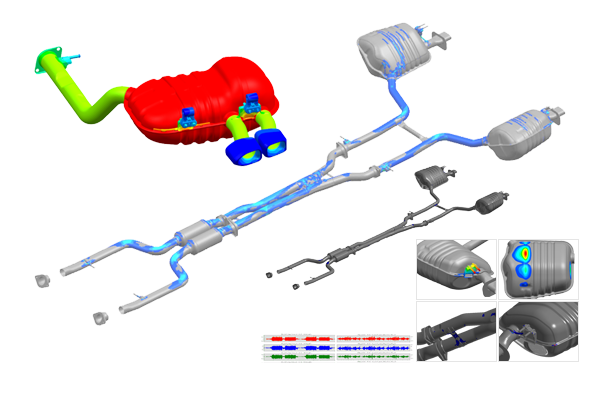

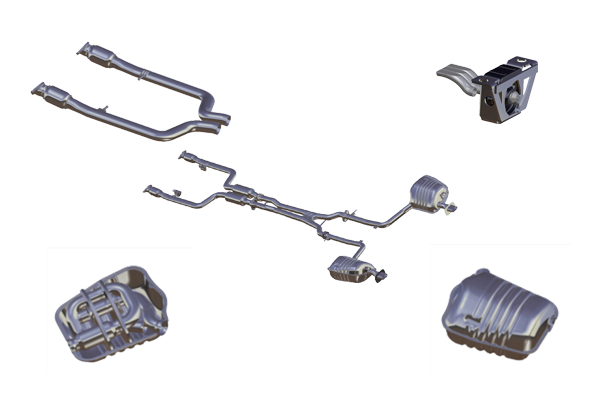

- Design Parts of muffler

-

-

- Layout

- - Pipe route design for exhaust gas induction

-

- RESO' Volume

-

- Check for RESO' volume possibilities

- Check the relative part clearance to secure the volume

-

- Mounting

- - Connect body to muffler, vibration insulation

-

- Tuning

-

- Tune muffler noise reduction, effect of vehicle interior noise

- Tune sound quality, sporty sound, popping sound

-

-

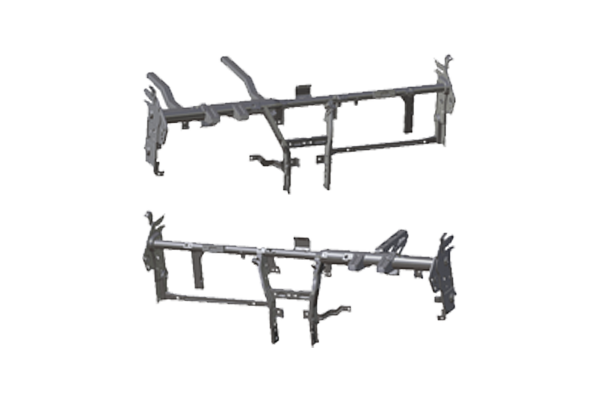

- CCB (Car Cross Beam) Design Parts of muffler

-

-

- Layout

- - Configuration design to meet different package types

-

- Durability

- - Designed to satisfy the durability from vehicle vibration

-

- Assembly & Weld

- - Designed for ease of assembly with tolerance reflection and weld thermal deformation

-

Analysis

The analysis achieves the best product performance

and optimal design models using virtual simulation

with the help of virtual simulation.

Moreover, it realizes the best design model through optimal design methods on performance,

price and mass of products.

-

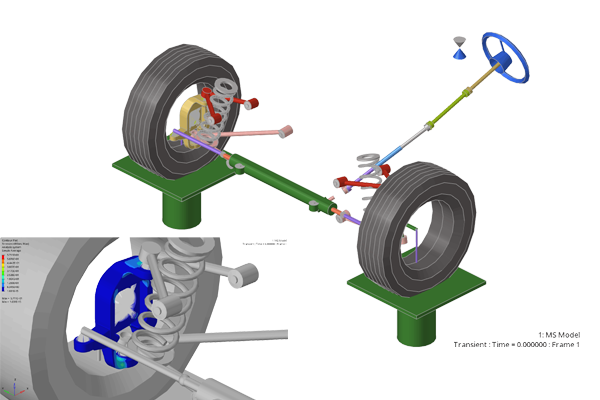

- Structure Analysis

-

-

- Purpose

- Evaluation of the structural performance of the products

-

- Products

- Exhaust system, Hydrogen exhaust system, Electronic device, Chassis module, Battery system

-

- Programs

- ABAQUS, NX NATRAN, nCode

-

-

- Collision Analysis

-

-

- Purpose

- Evaluation of compliance with safety regulations in the event of a collision

-

- Products

- Chassis module, Battery system

-

- Programs

- ABAQUS, HYPERWORKS

-

-

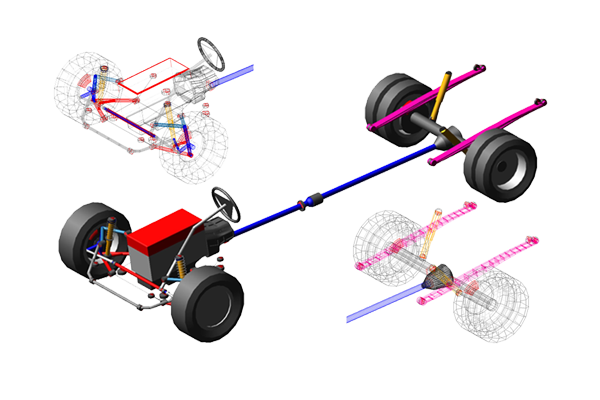

- Dynamic Analysis

-

-

- Purpose

- Evaluation of the product's dynamic performance

-

- Products

- Electronic device, Chassis module

-

- Programs

- ADAMS, HYPERWORKS

-

-

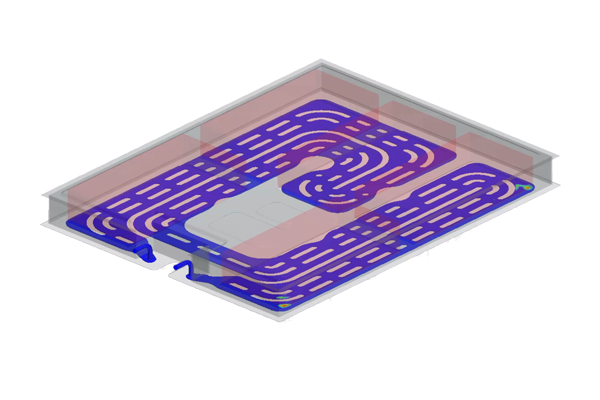

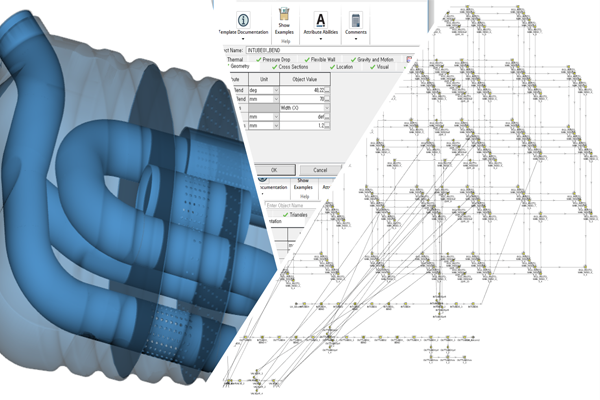

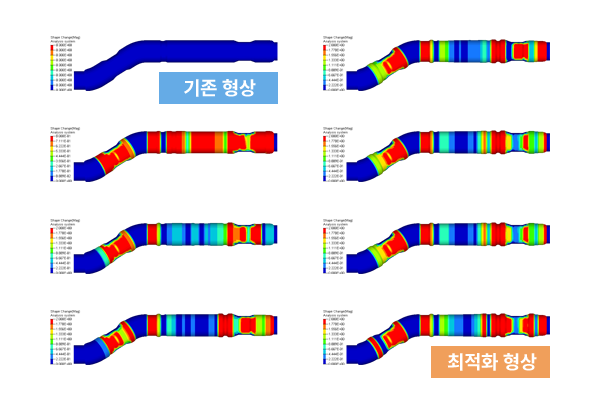

- CFD Analysis

-

-

- Purpose

- Evaluation of the CFD's performance of the products

-

- Products

- Exhaust system, Hydrogen exhaust system, Electronic device, Battery system

-

- Programs

- Star CCM+, SC-TETRA

-

-

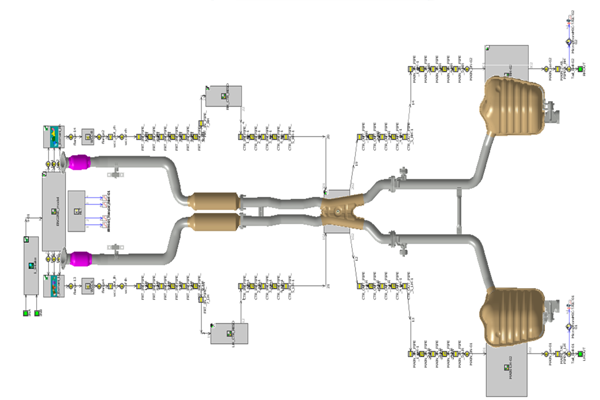

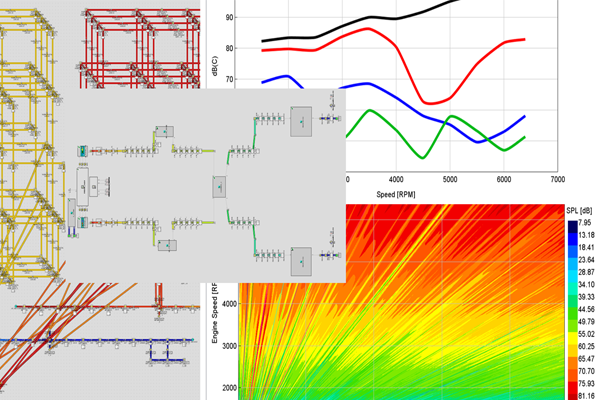

- Acoustic Analysis

-

-

- Purpose

- Evaluation of the acoustical performance of the products

-

- Products

- Exhaust system

-

- Programs

- GT-POWER, WAVE

-

-

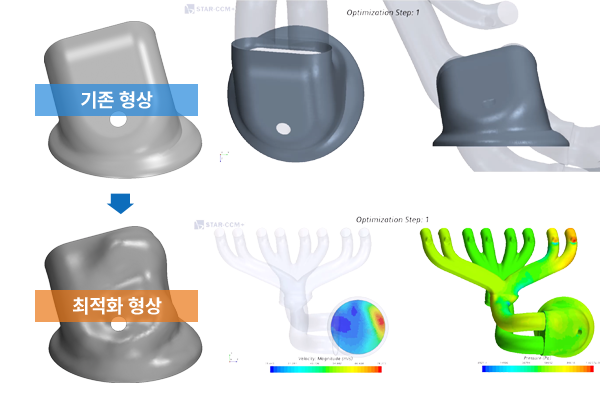

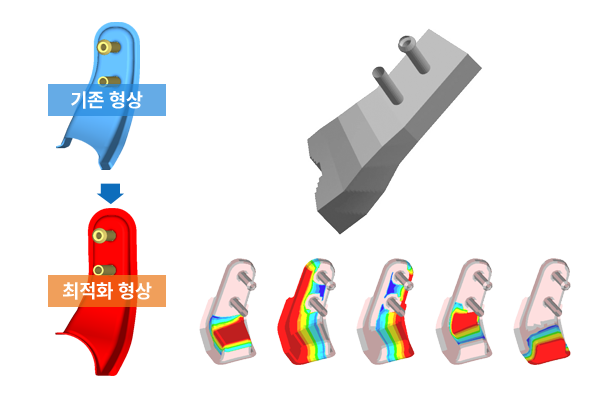

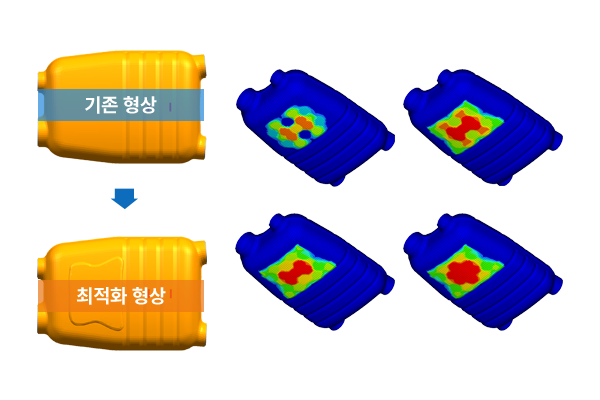

- Optimization Analysis

-

-

- Purpose

- The decision of an optimal design model that meets product performance

-

- Products

- Exhaust system, Hydrogen exhaust system, Electronic device, Chassis module, Battery system

-

- Programs

- HYPERWORKS, TOSCA, iSIGHT

-

Test

Based on overall test and verification, we challenge the best quality products.

We fully validate and develop products in the process of product development through simulatingactual field conditions on durability, performance and reliability test

-

-

Durability

Test Engine Dynamometer (Durability) Test

Request -

-

- Durability Test

- P/T related components durability test

-

- Test Prouduct

- Exhaust system

-

- Test Equipment

- Engine Dynamometer

Engine Dynamometer (Durability)Equipment Quantity1Equipment SPECAC : 370kW / MAX : 8,000RPM -

-

Durability

-

-

Durability

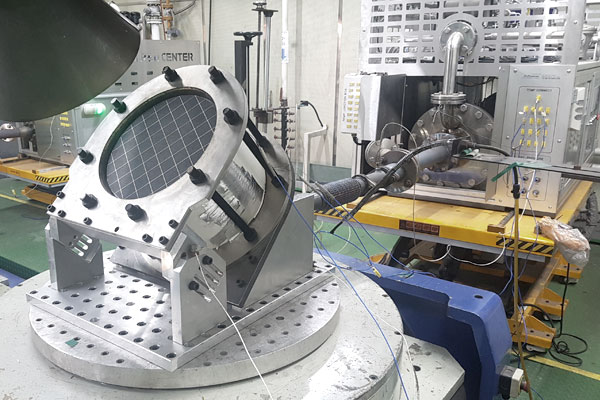

Test Vibration Test Test

Request -

-

- Durability Test

- Hot & Cold vibration test , Jig Design & Making

-

- Test Prouduct

- Exhaust system

-

- Test Equipment

- Electromagnetic Shaker, Burner

Electro Shaker(Duralbility)Equipment Quantity 2Equipment SPEC Max Load : 7ton / 18ton

Freqeuncy Range : 5 to 2,200Hz

Max Disp. : 51mm

Test Mode : Sine, Random, Sine on Random

Burner : 1,100℃ / 1,000kg/h -

-

Durability

-

-

Durability

Test Thermal Durability Test Test

Request -

-

- Durability Test

- Thermal Fatigue, Thermal Shock Test(Water spray)

-

- Test Prouduct

- Exhaust system

-

- Test Equipment

- Thermal Fatigue/Shock Tester, Burner

Thermal Fatigue/ Thermal Shock TesterEquipment Quantity4Equipment SPEC Max Temp : 1,000℃

Max Flow rate : 500kg/h -

-

Durability

-

-

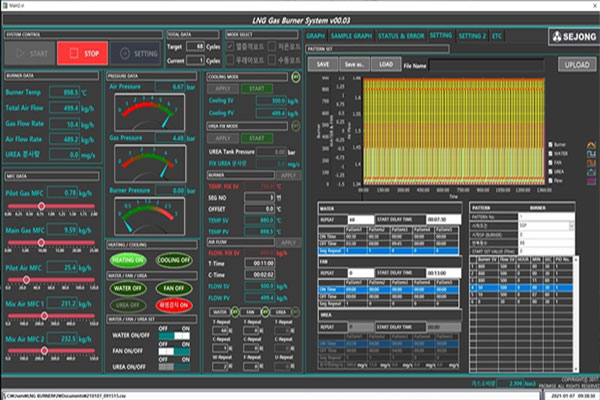

Durability

Test FatigueTest Test

Request -

-

- Durability Test

- Component Fatique Test, Component Load - Life Test

-

- Test Prouduct

- Exhaust system, Vehicle Component

-

- Test Equipment

- Hydraulic Actuator, Gas Burner

Hydraulic Actuator / Gas BurnerEquipment Quantity24ch.Equipment SPEC Max Frequency : 50Hz

Max Disp. : 150mm

Max Load : ±5kN / ±10kN

Gas Burner : 4EA, Max Temp. 900℃ -

-

Durability

-

-

Durability

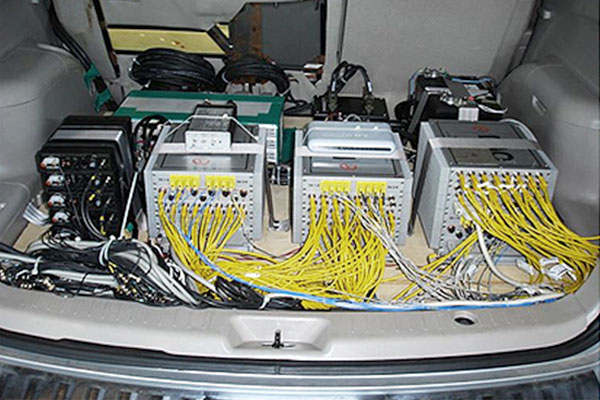

Test Data Acquisition & Signal Analysis Test

Request -

-

- Durability Test

- Vehicle Road load / Temp. / Displacement / Acceleration Simulation testing

-

- Test Prouduct

- Exhaust system, Vehicle Component

-

- Test Equipment

- eDAQ, nCode

Data Acquisition System (eDAQ)Equipment Quantity2 SETEquipment SPEC Force Transducer

LVDT, String Pot

Strain Gage, Accelerometer

Temperature

Vehicle Bus(CAN), GPS -

-

Durability

-

-

Durability

Test Corrosion Resistance Test Test

Request -

-

- Durability Test

- Combined Environmental Test , Salt spray Test, Corrosion Test

-

- Test Prouduct

- Exhaust system, Automotive application component

-

- Test Equipment

- Combined Environmental Test Chamber

Combined Environmental Test ChamberEquipment Quantity1Equipment SPEC Temp. Range : 0~80℃

Temp. Precision : ±0.1℃ at 80℃

Humidity Range : 30~95% R.H.

Precision : ±0.2℃ at 50℃ph -

-

Durability

-

-

Durability

Test Thermal Shock Tester

(HEUNGDEOK R&D Center) Test

Request -

-

- Durability Test

- Thermal Shock Test, Cold/Room/Hot Environmental Test

-

- Test Prouduct

- Sensor, Valve, Actuator

-

- Test Equipment

- Thermal Shock Tester

Thermal Shock TesterEquipment Quantity1Equipment SPEC Test Zone : 2

Hot Chamber Temp. range : 25~200℃

Cold Chamber Temp. range : -50℃~0℃

Function : Programmed Cycle -

-

Durability

-

-

Durability

Test Cold/ Hot Environmental Chamber (HEUNGDEOK R&D Center) Test

Request -

-

- Durability Test

- Cold/ Hot Environmental Test

-

- Test Prouduct

- Sensor, Valve, Actuator, Exhaust System, Automotive application component

-

- Test Equipment

- Cold/ Hot Environmental Chamber

Cold/ Hot Environmental ChamberEquipment Quantity 4Equipment SPEC Chamber Capacity : 420 Liter

Temp. range : -35~180℃

Heating rate : 2.0℃/℉ per min (-40~120℃)

Cold rate : 2.1℃/℉ per min (-40~120℃) -

-

Durability

-

-

Performance

Test Engine Dynamometer (Performance) Test

Request -

-

- Performance Test

- Tailpipe Noise/Radiation Noise/Backpressure, Drain Performance Test

-

- Test Prouduct

- Exhaust System, Automotive application component

-

- Test Equipment

- Anechoic Chamber, Engine Dynamometer

Anechoic ChamberEquipment Quantity1Equipment SPEC Indoor Effective Dimension : 8.2x64x4.6m

Cut-off Freq. : 75Hz

Background Noise : Air conditioning system OFF 16.0dB, Air conditioning system ON 25.5dBEngine Dynamometer (Performance)Equipment Quantity2Equipment SPEC DC : 220kW / Max : 6,000rpm

AC : 300kW / Max : 8,000rpm -

-

Performance

-

-

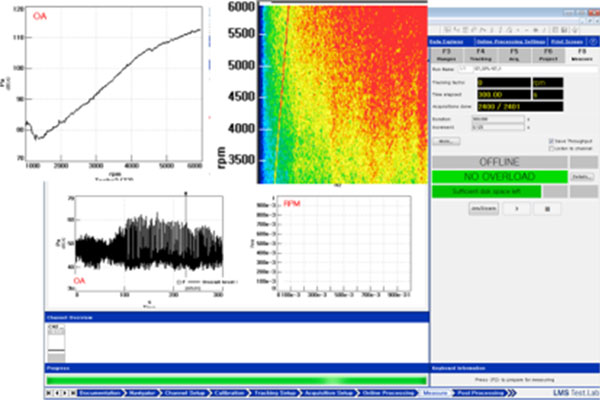

Performance

Test Data Acquisition & Signal Analysis Test

Request -

-

- Performance Test

- Vehicle NVH Test, FRF, MODAL Test

-

- Test Prouduct

- Exhaust System, Automotive application component

-

- Test Equipment

- LMS System

LMS SystemEquipment Quantity4Equipment SPEC - H/W : AC/DC/ICP coupling, Input Range 2.5mV ~ 10V

- S/W : OA, Order Tracking, Impact & Modal Testing -

-

Performance

-

-

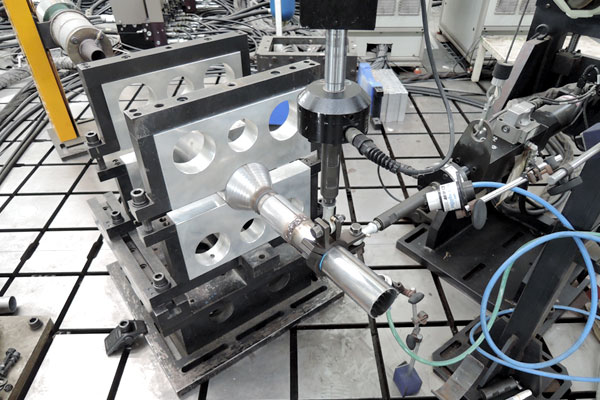

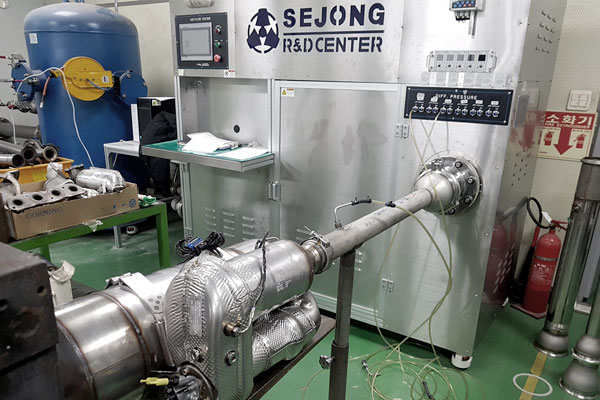

Performance

Test Air Flow Test Test

Request -

-

- Performance Test

- Exhaust/DPF Backpressure efficiency Test, Exhaust System Condensate Freezing Test, Drain Performance Test

-

- Test Prouduct

- Exhaust System

-

- Test Equipment

- Air Flow Tester

Air Flow Tester (Compressor Type)Equipment Quantity1Equipment SPEC Max Flow : 2,400kg/h

Measurement Range : 100kPa

Measurement Resolution : 0.1kPaAir Flow Tester (Blower Type)Equipment Quantity2Equipment SPEC Max Flow : 800kg/h

Measurement Range : 30kPa

Measurement Resolution : 0.01kPa -

-

Performance

-

-

Performance

Test Chassis Dynamometer

(China R&D Center) Test

Request -

-

- Performance Test

- Exhaust Tailpipe noise, Radiation noise test

-

- Test Prouduct

- Exhaust system

-

- Test Equipment

- Anechoic Chamber, Chassis Dynamometer

Anechoic Chamber, Chassis DynamometerEquipment Quantity1 SETEquipment SPEC 1) Anechoic Chamber

- Chamber dimension: 13x16.5x10m [WxDxH]

- Cut-off Freq.: 80Hz

2) Chassis Dynamometer

- Wheelbase: 2350 ~ 4500mm

- Max. Speed: 200km/h -

-

Performance